Manufacturing company SPC

More than 50 years of experience

East Coast SPC is the first SPC manufacturing company in Spain. Its development is motivated by the growing demand for LVT and SPC flooring in the American and European markets.

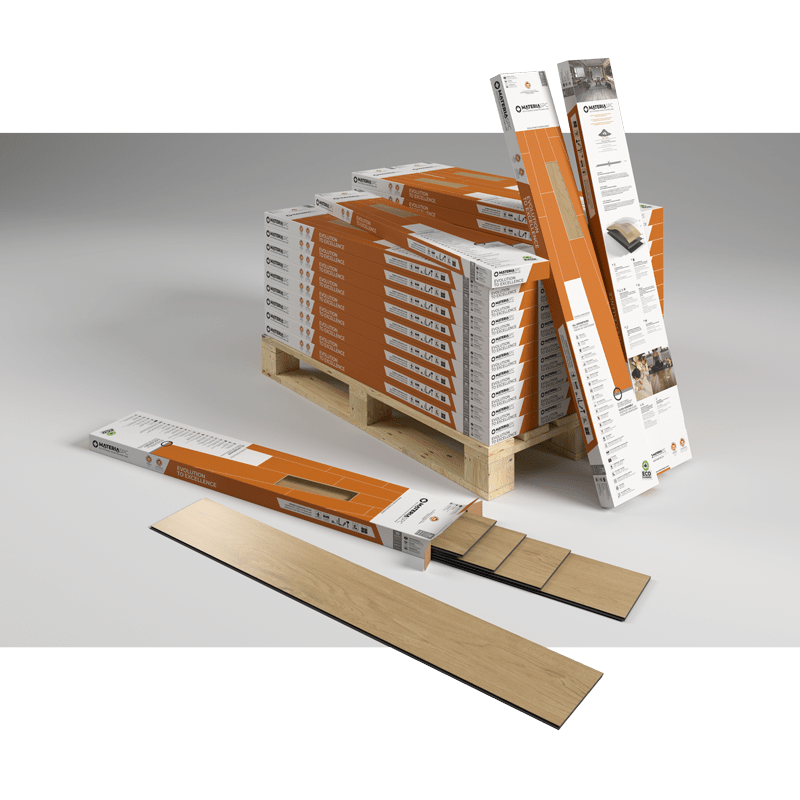

The new company has invested 11.5 million euros in machinery and has established the first production plant in Alicante with more than 20,000 m2 of floor space. The production capacity will be 1.8 million m2/year during the first year and more than 4 million m2/year from the second year onwards.

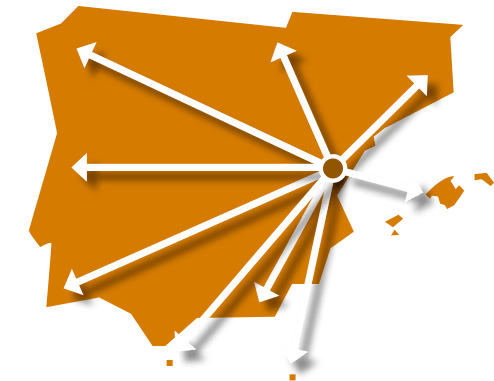

Immediate replacement service

Logistics & Service

The quantity does not matter. From our logistics center we guarantee the delivery of your order in record time.

You will save space in your facilities by not needing to store product stock and peace of mind knowing that your order will be delivered in the set time.

No delays.

Manufacture “à la carte”

for large projects

Make Your Own Pavement “Recipe”

We put at your disposal all our manufacturing potential to adhere to your specifications based on your needs, covering all the technical aspects of the final product, combinations of materials and thicknesses, advice, dimensions, finishes and of course design, to create the perfect flooring that your big project requires. Always within the required quality standards.

We are open to any proposal that you could make us. Contact us.

We would like to count on the collaboration of your company to develop the new collections.

WE WILL BE THE FIRST EUROPEAN COMPANY TO PRODUCE SPC IN SPAIN

Recyclable and with no CO2 footprint in its manufacture.

Greater use of resources and less waste generation to increase sustainability and care for the environment. This is our philosophy.

We produce our MATERIA SPC floors exclusively with electrical energy from 100% renewable sources (80% from our own solar panels) generating a zero footprint in CO2 emissions and we minimize the generation of waste by reincorporating the remains of the materials used back into the manufacturing process.

The quality of our products allows them to be reused, extending their useful life, in addition to not requiring other products (such as adhesives or additional supports) during installation, resulting in a fully recyclable product once its cycle of use is over.