El merecido éxito de los suelos vinílicos MATERIA SPC frente a LVT, WPC y MADERA.

Matter SPC deserved excellence

Comparison of SPC flooring

Comparative tests against other rigid SPC floor coverings demonstrate the excellent qualities of our high quality MATERIA SPC mineral composite floorings, far outperforming SPC floors manufactured to date.

Undoubtedly, SPC MATERIA SPC floors have a lot of weight when it comes to deciding on the purchase decision compared to other products. A coating for all types of interiors without rival.

Ultra-tough SPC material has a much harder core than any of the conventional vinyl flooring types marketed to date, such as LVT, WPC and even laminate flooring.

Our core consists of a mixed composition of minerals and other components pressed at very high density. 77% Mineral + 23% other components. An extraordinary combination that makes the difference.

It confers high impact resistance and dimensional stability, thus avoiding the typical contraction/dilatation movements that can lead to open joints or lifting of the floor caused by changes in humidity and ambient temperature. The dimensional stability of MATERIA SPC vinyl flooring makes it possible to install larger surfaces than usual without having to use expansion joints. They are not necessary except in cases where the area to be covered exceeds 15 linear meters from end to end (225 m2).

SPC rigid floors

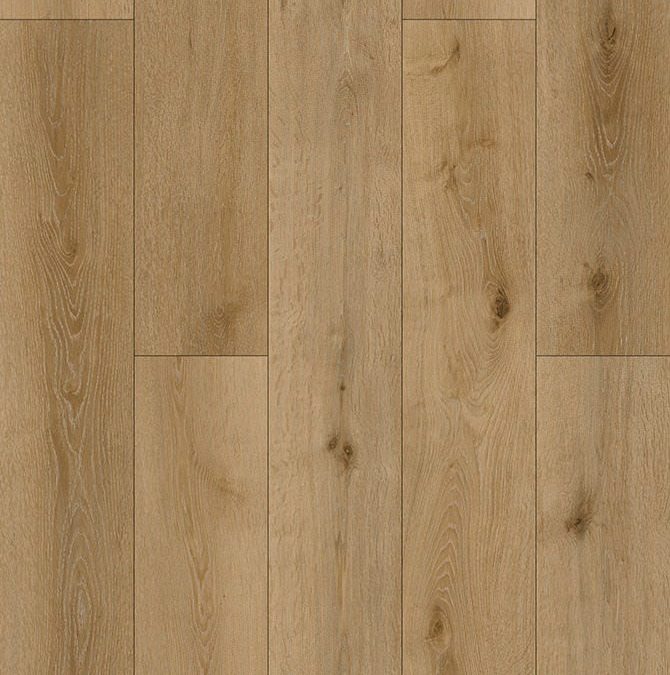

SPC (Stone Plastic Composite) flooring is a type of floor covering that combines several layers to achieve durability, water resistance and dimensional stability.

- Composition: The core of SPC flooring is made of a mixture of stone powder (mainly limestone powder) and plastic polymers, usually polyvinyl chloride (PVC). This combination results in a solid and resistant material.

- Dimensional stability: The stone and plastic core gives SPC flooring high dimensional stability, which means it is less prone to expand or contract in response to changes in humidity or temperature.

- Water Resistance: Unlike some other types of floor coverings, SPC is water resistant, making it suitable for moisture-prone areas such as kitchens and bathrooms.

- Appearance: Like other types of vinyl wood flooring, SPC flooring is available in a variety of designs that mimic the appearance of natural woods, stone and other materials.

- Installation: It is usually installed by means of a click system, which facilitates installation without the need for glue. It can also be installed over existing floors.

- Wear resistance: The top layer of SPC flooring is wear resistant, providing protection against scratches, stains and other signs of wear.

- Easy maintenance: Like other vinyl flooring, SPC flooring is easy to clean and maintain with a vacuum cleaner and damp mop.

- Acoustic insulation: MATERIA SPC includes additional layers to improve acoustic insulation properties, reducing impact noise.

SPC rigid flooring has become popular due to its durability, water resistance and versatility in terms of design. It is a suitable choice for residential and commercial environments.

LVT flooring is a type of floor covering called Luxury Vinyl Tile (LVT).

LVT is a synthetic material that mimics the appearance of natural materials such as wood or stone. LVT is mainly made of polyvinyl chloride (PVC) and resins. This gives it durability and water resistance. It is installed floating over the existing floor. It does not adhere directly to the subfloor. It is often installed over a layer of foam or cork that provides some degree of sound insulation and walking comfort.

WPC flooring

“WPC flooring” refers to a type of floor covering that uses Wood Plastic Composite (WPC) technology.

El WPC combina fibras de madera con polímeros plásticos, generalmente polietileno de alta densidad (HDPE) or polypropylene This blend creates a material that combines the natural look of wood with the durability of plastic.

Like LVT flooring, WPC flooring comes in a variety of designs that mimic the appearance of wood. It is usually installed in a floating manner, not adhered directly to the subfloor.

Unlike natural wood, WPC flooring is water resistant. This makes it suitable for moisture-prone areas such as kitchens and bathrooms.

Wooden floor

Wood flooring is a classic and timeless choice that adds warmth and elegance to any space. Wooden floors can be made of various species of trees: oak, maple, walnut, cherry, pine, among others. Each type of wood has its own color and grain characteristics.

Wood floors can be nailed, glued or floating.

The durability of wood floors varies according to the species of wood and the finish applied. They require some maintenance to preserve their beauty. Avoid excessive humidity and apply occasional finishing products to maintain its shine and protection.

Laminate Flooring

Laminate flooring is composed of several layers fused together through a lamination process. These layers generally include:

- a base coat,

- a layer of high density fiber core (HDF),

- a printed design layer that mimics the appearance of wood,

- and a transparent wear-resistant top layer.

Laminate flooring is composed of several layers fused together through a lamination process. These layers generally include a base layer, a high-density fiberboard (HDF) core layer, a printed design layer that mimics the appearance of wood, and a transparent wear-resistant top layer.

Laminate flooring is composed of several layers fused together through a lamination process. These layers generally include a base layer, a high-density fiberboard (HDF) core layer, a printed design layer that mimics the appearance of wood, and a transparent wear-resistant top layer. Some laminate floors have acoustic insulation properties, which means they can help reduce impact noise and transmitted sounds.

5 working days to any point of the peninsula

The amount doesn’t matter. From our logistics center we guarantee the delivery of your order in record time. You will gain space in your facilities by not needing to store product stock and peace of mind knowing that your order will be delivered on time. No delays.

FOR LARGE ORDERS (several containers) we offer you our exclusive “à la carte” product service with which you can create your own configuration of the piece: combining materials and thicknesses of the layers according to the technical, aesthetic and economic requirements of the final product you wish to obtain.

We put at your disposal all our manufacturing potential to adhere to your technical specifications according to your needs, covering all the technical aspects of the final product, combinations of materials and thicknesses, advice, dimensions, finishes and of course design, to create the perfect pavement that your big project requires. Always within the required quality standards. We are open to any proposal you may have. Contact with us